You can not select more than 25 topics

Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

|

|

8 years ago | |

|---|---|---|

| .. | ||

| MCAD@0e57f5500a | 8 years ago | |

| OpenSCAD-Pattern-Filling@24b508235e | 8 years ago | |

| doc | 8 years ago | |

| README.md | 8 years ago | |

| box.scad | 8 years ago | |

| common.scad | 8 years ago | |

| cover.scad | 8 years ago | |

| slic3r-config.ini | 8 years ago | |

README.md

An enclosure for a lab-bench PSU

Context

The goal of this project was to make an enclosure for my lab-bench power supply, made of an old ATX power supply.

The problem was that the existing case was made of metal and too small for the additional hardware. This lead to short circuits sometimes.

You can find this project on Thingiverse: https://www.thingiverse.com/thing:2954456

Design

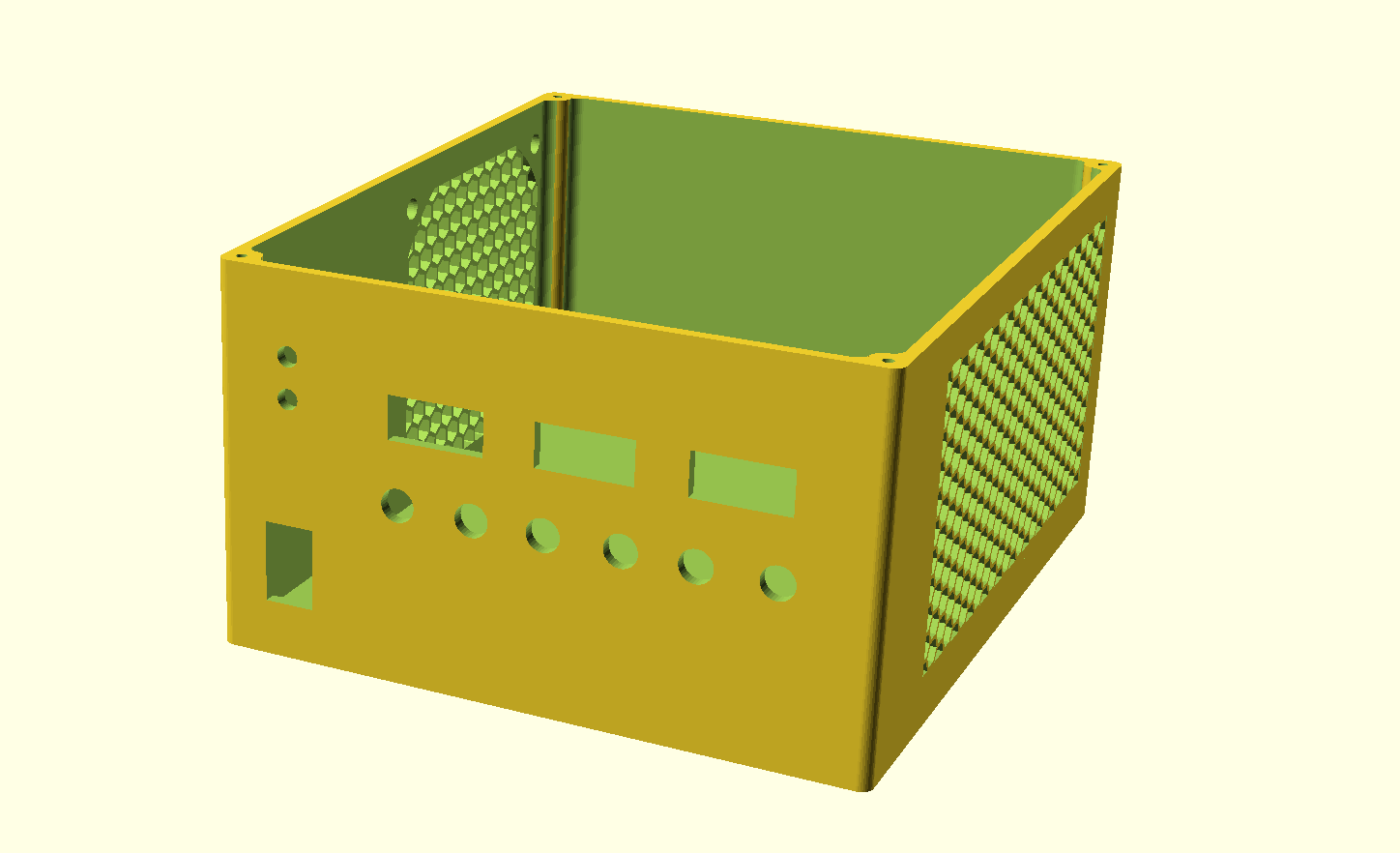

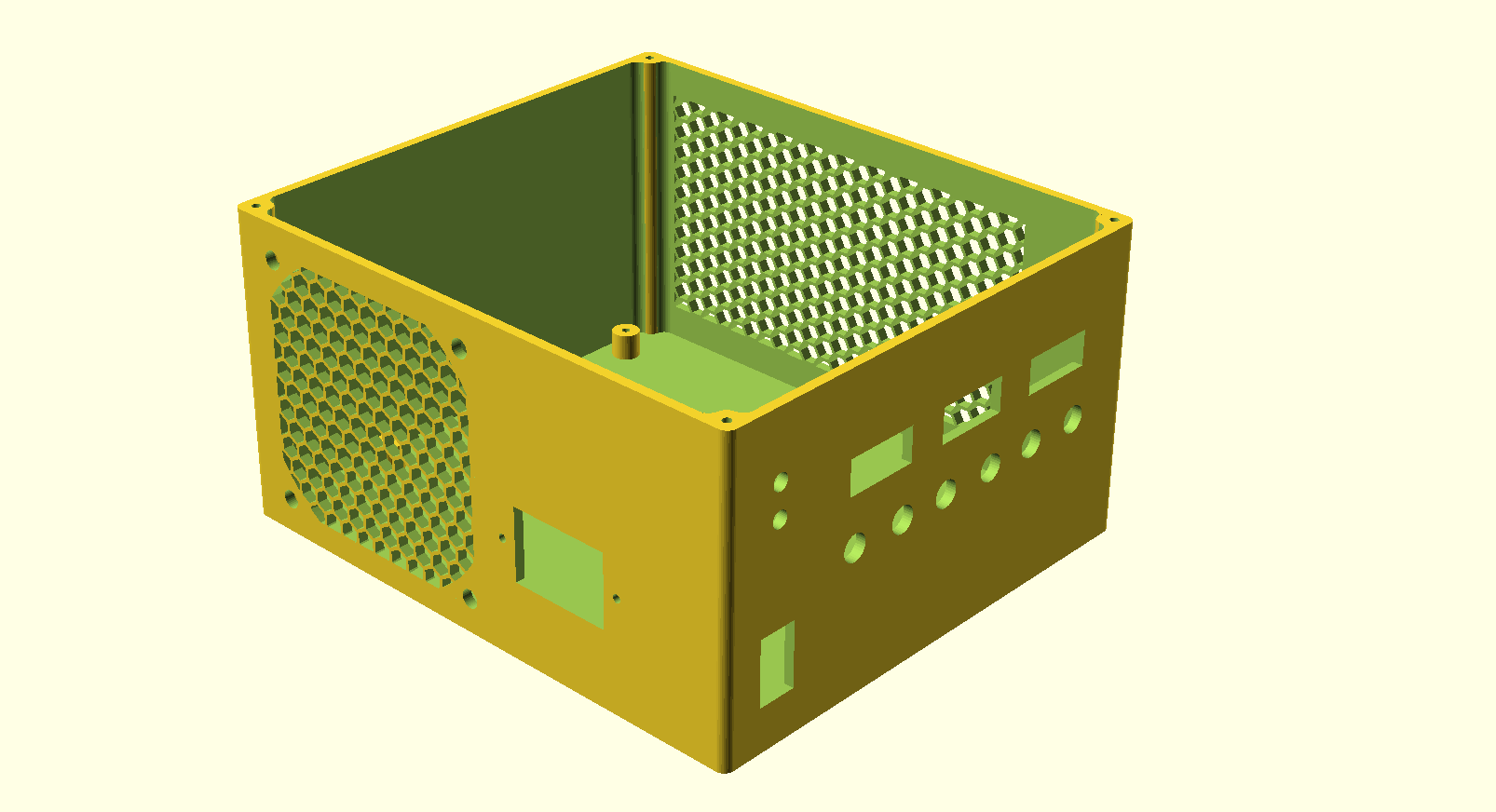

The box (box.scad):

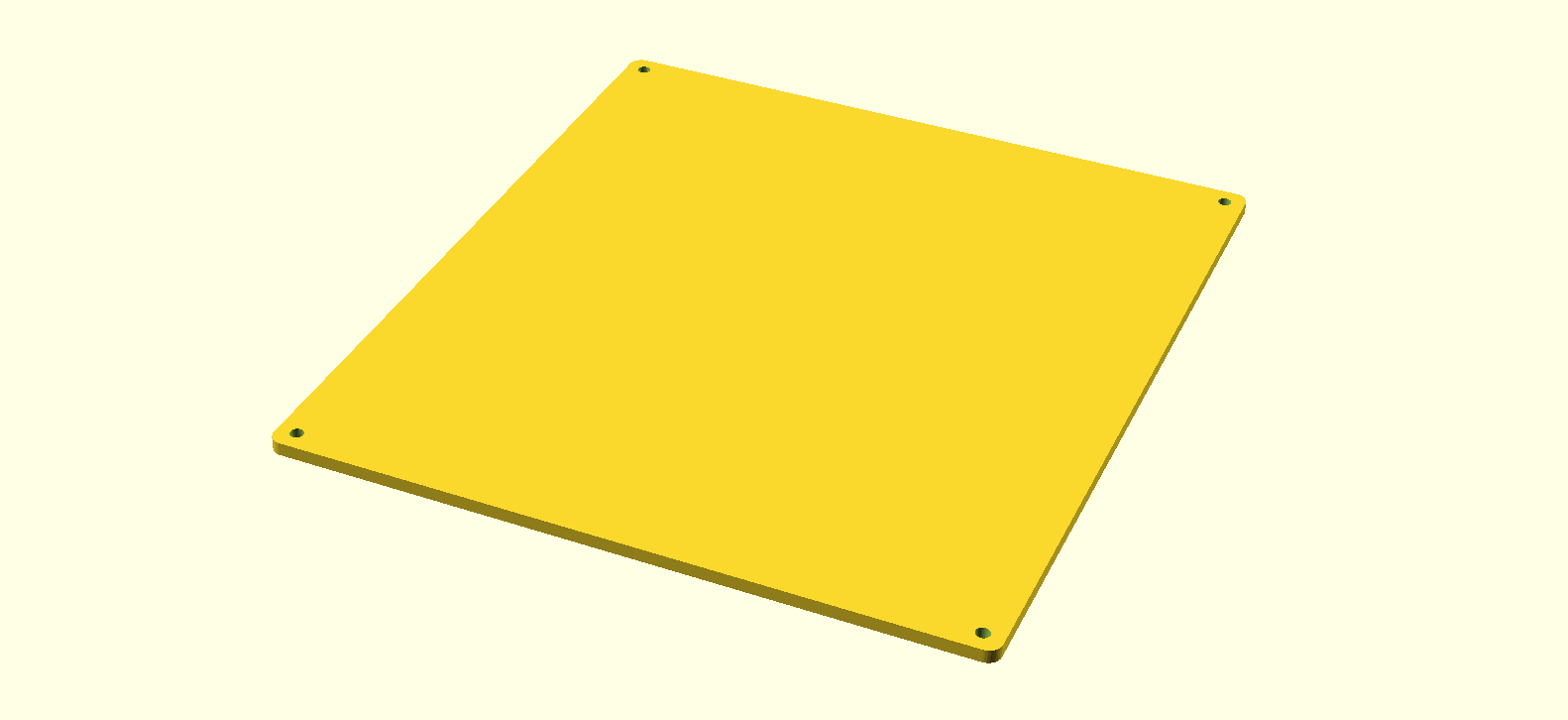

The cover (cover.scad):

Final dimensions (common.scad):

The final dimensions of both the cover and the box are

defined in common.scad.

3D Printing

I printed both parts using a custom Slic3r config:

- Layer height: 0.2

- Vertical Shells / Perimeter: 5

- Infill: 100%

- No support material

Bill of Material

- ~400g PLA filament

- 6x DANIU 4mm Terminal Banana Plug Socket Jack Connectors

- 3x Geekcreit® 0.28 Inch 2.5V-30V Mini Digital Volt Meter

- 2x 5mm LED

- 4x M3 screw

- an old ATX power supply

Remaining work

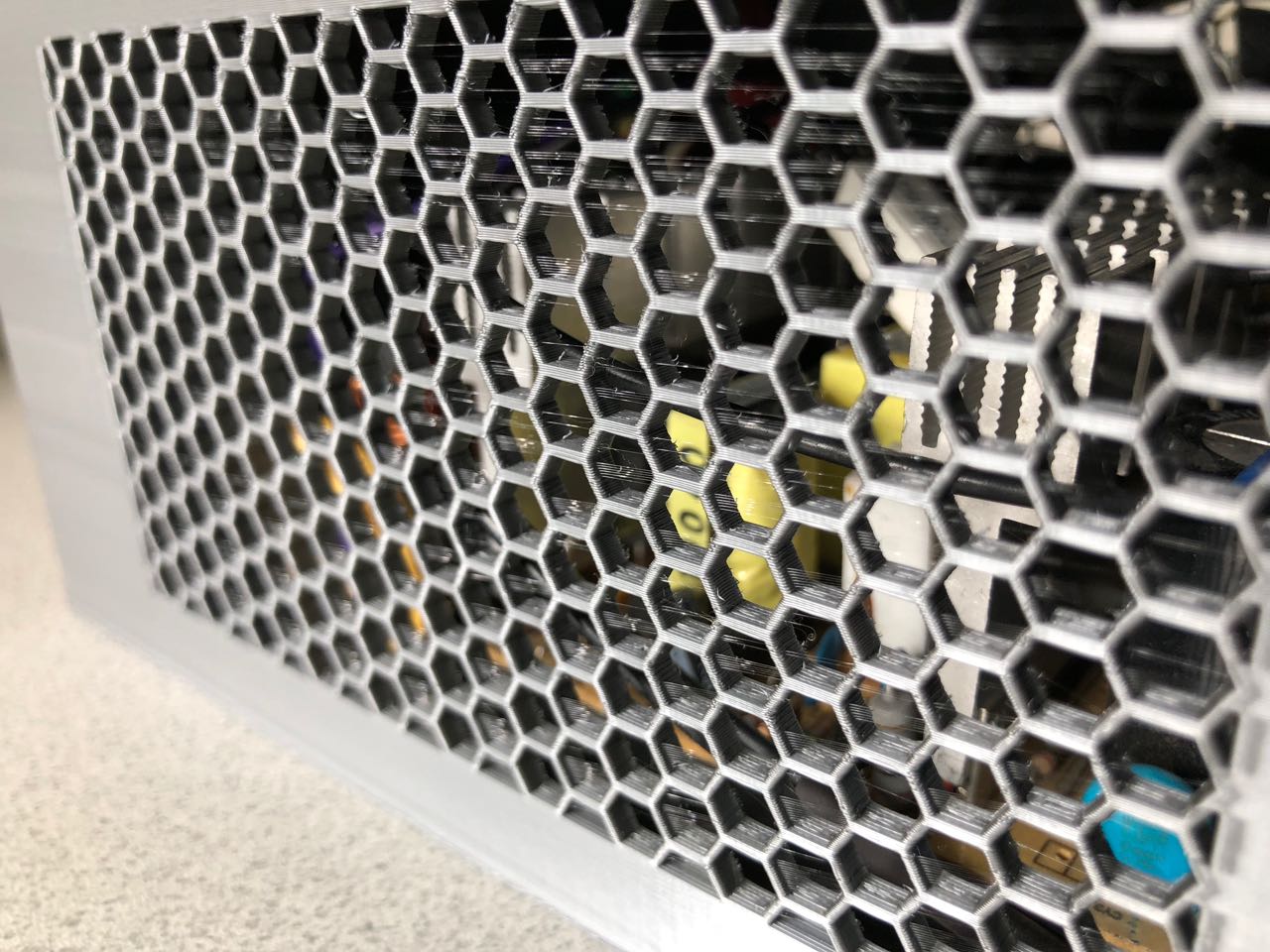

The alveolus vents pattern is maybe a bit too thin and fragile.

If I need to reprint it, I would increase the vent_margin in common.scad

to something like 2 mm and maybe vent_alveolus_size to 8 mm.